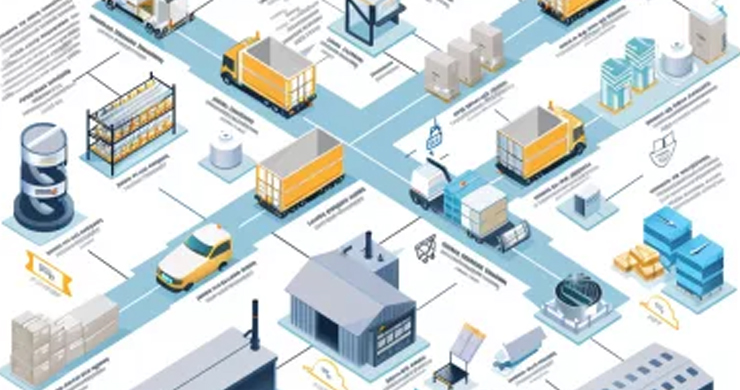

Warehouse automation is a constantly evolving trend, driven by the need to optimize logistics processes and increase operational efficiency. Robotics has emerged as a key element in this transformation, enabling businesses to handle inventories with greater precision, speed, and flexibility. In this article, we will explore how robotics is revolutionizing warehouse automation and why it is considered essential for the warehouses of the future.

Introduction to Robotics in Warehouse Automation

Robotics in warehouse automation is not a new concept; however, recent technological advancements have greatly expanded its potential. Robots are no longer just simple machines performing repetitive tasks. Today, they are equipped with artificial intelligence (AI), advanced sensors, and machine learning capabilities that allow them to adapt to changing environments and continuously improve their performance.

What is Robotics in Warehouses?

Robotics in warehouses refers to the implementation of robots to automate various tasks within a logistics center. These tasks can include the picking and packing of products, the transport of goods within the warehouse, and inventory management. Robots can operate autonomously or in conjunction with human workers, complementing their skills and enhancing overall efficiency.

Benefits of Robotics in Automation

- Increased Precision and Consistency: Robots are designed to perform tasks with extremely high precision, reducing the margin of human error and ensuring greater consistency in operations.

- Increased Operational Speed: Robots can work 24 hours a day, 7 days a week, without fatigue, allowing businesses to accelerate their logistics processes and handle larger volumes of work.

- Reduced Operational Costs: Although the initial investment in robotics can be high, long-term operational costs are reduced due to improved efficiency and the reduction of costly errors.

- Improved Space Management: Robots can operate in confined spaces and optimize warehouse layouts, allowing more efficient use of available space.

- Adaptability and Scalability: Robotic systems can be programmed and reprogrammed to adapt to new tasks or changes in demand, making them highly scalable.

Types of Robots Used in Warehouses

There are several types of robots commonly used in warehouse automation, each designed to fulfill specific functions.

Autonomous Mobile Robots (AMR)

AMRs are robots that can navigate autonomously through the warehouse using digital maps, sensors, and cameras. Unlike Automated Guided Vehicles (AGV), which follow predefined routes, AMRs can adapt to changes in the environment and optimize their routes in real-time.

Automated Storage and Retrieval Systems (AS/RS)

These automated systems include a combination of vertical shelving and robots that efficiently store and retrieve products. AS/RS are ideal for managing high-volume inventories and allow for maximizing vertical storage space.

Picking Robots

Picking robots are designed to select and pick products from shelves. Equipped with robotic arms and advanced sensors, they can handle a wide range of products, from fragile items to heavy objects.

Inventory Drones

Although not as common as terrestrial robots, inventory drones are gaining popularity. These drones can fly through the warehouse and perform a quick scan of the inventory, providing an accurate and real-time view of stock levels.

Use Cases: Companies Leading Robotic Automation

Numerous companies have already implemented advanced robotic solutions in their warehouses, achieving impressive results in terms of efficiency and profitability.

- Amazon is an undisputed leader in warehouse automation. The company uses a fleet of Kiva robots, now known as Amazon Robotics, to move entire shelves of products to workers who pick and pack them. This technology has significantly reduced order processing times and improved picking accuracy.

- Ocado, an online supermarket based in the UK, has developed one of the most advanced warehouse automation systems in the world. Their warehouses are equipped with robots that operate on a 3D grid, moving and organizing products in a highly efficient manner. This approach has enabled Ocado to handle thousands of daily orders with unprecedented speed and accuracy.

- Zebra Technologies has introduced mobile robots that work alongside human employees to optimize picking operations. These robots follow workers through the warehouse, helping them pick products and reducing the time it takes to complete orders.

Challenges and Considerations in Implementing Robotics in Warehouses

Despite their numerous benefits, implementing robotics in warehouses also presents challenges that companies must address.

Initial Costs

The cost of acquiring and implementing robotic systems can be prohibitive for some companies, especially for SMEs. However, it is important to consider the long-term savings and return on investment.

Integration with Existing Systems

Integrating robots into a warehouse that already has established processes can be complex. It is essential that robotic systems integrate seamlessly with Warehouse Management Systems (WMS) and other logistics software to maximize their effectiveness.

Resistance to Change

The introduction of robotics can generate resistance among employees, who may fear for the security of their jobs. It is crucial to manage change effectively, communicating the benefits of automation and offering training opportunities for workers to acquire new skills.

Maintenance and Technical Support

Robotic systems require regular maintenance and specialized technical support. Companies must be prepared to invest in these services to ensure the continuous operation of their warehouses.

The Future of Robotics in Warehouse Automation

The future of robotics in warehouse automation is promising. With continuous advancements in artificial intelligence, machine learning, and sensors, robots will become increasingly autonomous and capable of performing complex tasks without human intervention. Additionally, collaborative robotics, where robots work closely with humans, is expected to become a norm in the industry.

In the coming years, we will see greater adoption of robotics in warehouses of all sizes, from large distribution centers to small logistics facilities. This trend will not only improve operational efficiency but also allow companies to quickly adapt to market fluctuations and consumer demands.

Robotics is playing a fundamental role in the automation of warehouses, transforming the way companies manage their logistics operations. Although there are challenges in its implementation, the long-term benefits far outweigh the costs and initial efforts. As technology continues to advance, robotics will remain an essential pillar in creating the warehouses of the future, enabling companies to stay competitive in an increasingly dynamic market.

Warehouse automation with robotics is not just a trend; it is a necessity for companies looking to optimize their processes and provide better service to their customers. It is time for companies to embrace this technology and prepare for the future of logistics.